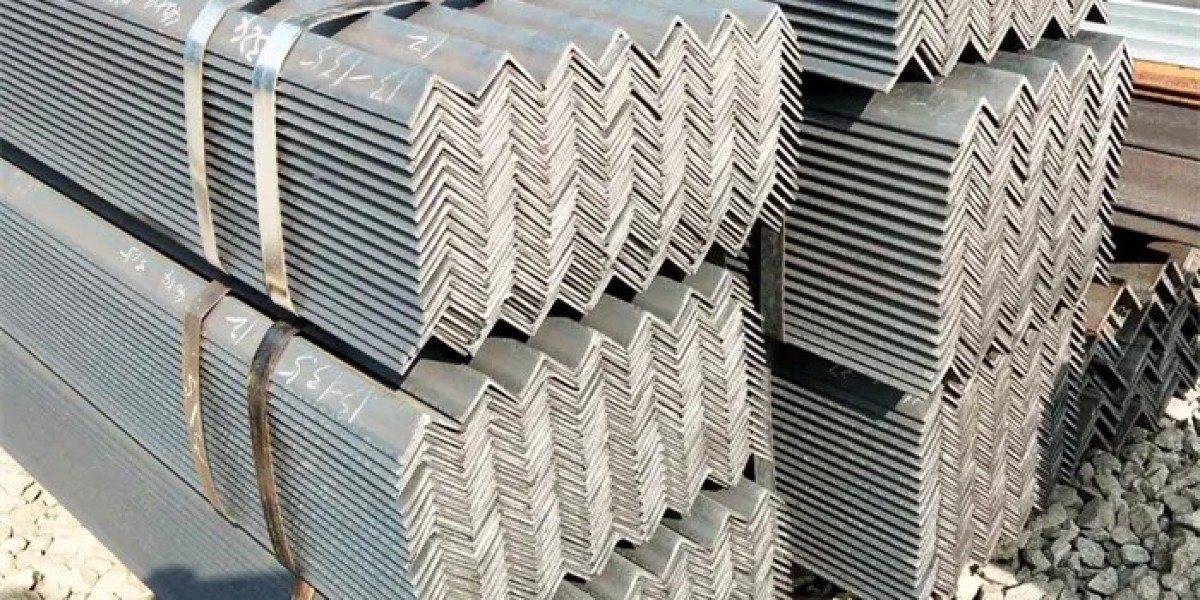

https://www.xs-metals.com/316L-Galvanized-angle-steel.htmlis a versatile and durable material that finds extensive use in various industrial applications. With its unique properties and protective coating, galvanized angle steel offers exceptional strength, corrosion resistance, and longevity. In this article, we will explore the benefits and applications of galvanized angle steel, highlighting its importance in industrial settings.

Understanding Galvanized Angle Steel

Galvanized angle steel is a type of steel that has been coated with a layer of zinc through a process called galvanization. This coating provides a protective barrier against corrosion, making galvanized angle steel highly resistant to rust and oxidation. The composition of galvanized angle steel typically consists of iron and carbon, with the addition of zinc for the galvanized coating.

The Galvanization Process

Galvanization involves immersing the angle steel in a bath of molten zinc, which adheres to the surface of the steel. This process creates a metallurgical bond between the zinc and the steel, resulting in a durable and long-lasting coating. The galvanized layer acts as a sacrificial barrier, protecting the underlying steel from corrosion.

Advantages of Galvanized Coating

The galvanized coating on angle steel offers several advantages that make it ideal for industrial applications. Firstly, it provides excellent corrosion resistance, even in harsh environments such as coastal areas or chemical plants. The zinc coating acts as a physical barrier, preventing moisture and corrosive substances from reaching the steel surface. Additionally, galvanized angle steel requires minimal maintenance, reducing the need for frequent inspections and repairs.

Strength and Durability

Galvanized angle steel is known for its exceptional strength and durability. It has high load-bearing capabilities, making it suitable for supporting heavy structures and equipment. The galvanized coating enhances the steel's resistance to impact and vibration, ensuring structural integrity even in dynamic industrial environments. Moreover, galvanized angle steel has a long lifespan, making it a cost-effective choice for industrial projects.

Corrosion Resistance

One of the primary advantages of galvanized angle steel is its superior corrosion resistance. The zinc coating acts as a sacrificial layer, corroding in place of the underlying steel. This sacrificial protection ensures that the steel remains intact and unaffected by rust or oxidation. As a result, galvanized angle steel can withstand exposure to moisture, chemicals, and other corrosive elements, making it suitable for a wide range of industrial applications.

Industrial Applications

Galvanized angle steel finds extensive use in various industrial applications. In construction, it is commonly used as structural support for buildings, bridges, and infrastructure projects. The strength and corrosion resistance of galvanized angle steel make it an ideal choice for manufacturing and fabrication processes, where it is used in the construction of machinery, equipment, and conveyor systems. Additionally, galvanized angle steel is widely employed in storage and warehousing solutions, providing sturdy shelving, racks, and support structures.

Advantages over Regular Steel

Compared to regular steel, galvanized angle steel offers several advantages. The galvanized coating provides enhanced corrosion resistance, making it suitable for applications where regular steel would be prone to rust and deterioration. Additionally, galvanized angle steel is cost-effective in the long run, as its extended lifespan reduces the need for frequent replacements or repairs. Furthermore, galvanization is a sustainable process, as it utilizes zinc, a recyclable material, and reduces the environmental impact of steel production.

Design Considerations

When using galvanized angle steel in industrial applications, certain design considerations should be taken into account. Proper sizing and dimensions are crucial to ensure structural integrity and load-bearing capacity. Connection methods, such as welding or bolting, should be chosen based on the specific requirements of the project. Galvanized angle steel also offers customization options, allowing for tailored solutions to meet the unique needs of industrial applications.

Installation and Maintenance

During installation, precautions should be taken to avoid damaging the galvanized coating. Sharp tools or abrasive materials should be avoided, as they can scratch or remove the protective layer. Regular inspection and cleaning are essential to maintain the integrity of the galvanized coating. Any signs of damage or corrosion should be addressed promptly to prevent further deterioration. In case of severe damage, repair or replacement of the galvanized angle steel may be necessary.

Case Studies: Real-World Examples

Galvanized angle steel has been successfully employed in numerous industrial projects. Industrial sheds and warehouses often utilize galvanized angle steel for their structural support, providing a robust and corrosion-resistant framework. Conveyor systems, which require sturdy and reliable support structures, benefit from the strength and durability of galvanized angle steel. Support structures for heavy machinery, such as cranes or manufacturing equipment, rely on galvanized angle steel for their load-bearing capabilities and corrosion resistance.

Conclusion

Galvanized angle steel is an indispensable material in various industrial applications due to its exceptional strength, durability, and corrosion resistance. Its protective coating ensures a longer lifespan, making it a cost-effective solution for industrial projects. Whether used in construction, manufacturing, or storage facilities, galvanized angle steel provides the necessary support and structural integrity required in demanding environments. By understanding its benefits and proper implementation, industries can harness the full potential of galvanized angle steel to achieve reliable and long-lasting solutions.

Xusheng Steel Limited is located in China steel production base Jiangsu Province. It is a large steel enterprise integrating production, processing and sales. Our factory was established in 2005, with 6 production lines, the main products including carbon steel series, stainless steel series, galvanizes series and aluminum series. The products are divided into plates, bars, pipes, coils, whole coils, plate surface finishing products, medium and heavy plates, weathering steels, wear-resistant steels, hot-rolled coils, cold-rolled coil, ppgi, galvanized steel coil, H-beam, excellent special steel, hot-rolled ribbed steel bar, etc., which are widely used in automobile, petroleum, railway, bridge, construction, electric power, transportation, machinery, shipbuilding, light industry, household appliances and kitchen There are many important fields.

Welcome to inquiry if you need to know more about galvanized angle steel details or order wholesale.

E-mail:xushengmetals@163.com