In the ever-changing landscape of the construction industry, efficiency, precision and durability are essential. One machine that can meet these demands is the mixing extruder. Manufactured by KeLi Machine, the mixing extruder is designed to meet the stringent requirements of mixing and extruding materials such as concrete, mortar and plaster. But what makes these extruders so effective? This article takes an in-depth look at how a mixing extruder works.

The Essence of Agitating Extruders

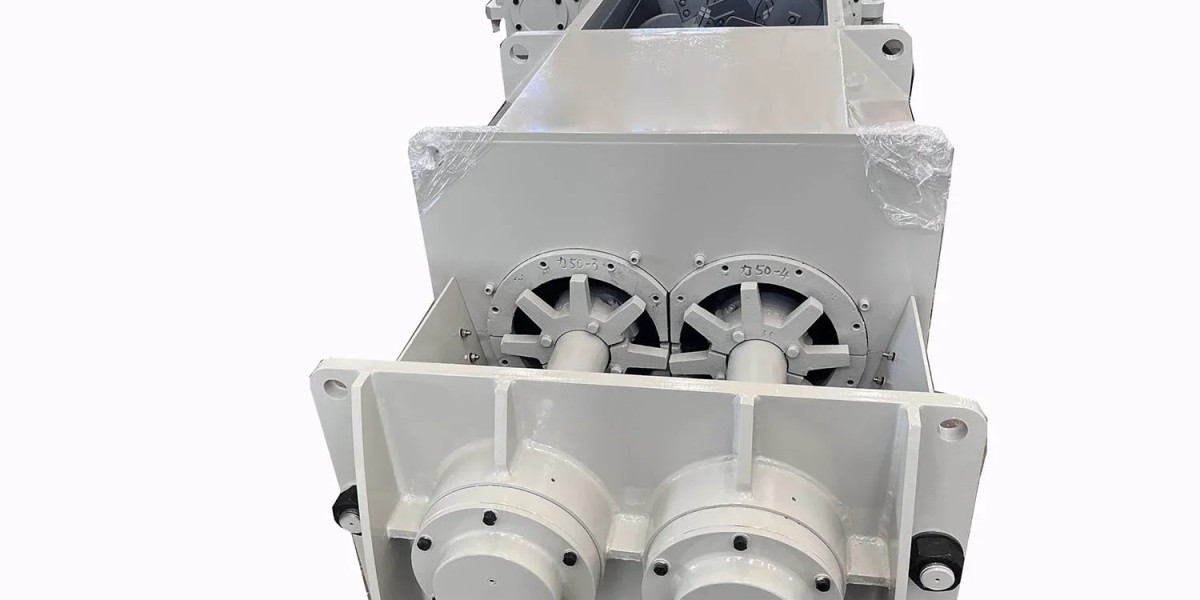

At its core, an https://www.yxkelijixie.com/Agitating-Extruder.html is a sophisticated piece of equipment engineered to mix and process materials with high efficiency. The machine operates on the principle of combining mechanical agitation with the process of extrusion. This dual-action approach ensures that materials are not only thoroughly mixed but also shaped and formed under pressure, resulting in a consistent and uniform output.

Key Features of the Agitating Extruder

The Agitating Extruder is equipped with several features that contribute to its superior performance:

High-Performance and Durability: Constructed using advanced technology and high-quality materials, these extruders are built to last. Their robust design ensures they can withstand the wear and tear of continuous operation in demanding environments.

Efficient Mixing and Extruding: The machine is capable of handling large volumes of material efficiently. Its design allows for the thorough mixing of components, ensuring a homogenous blend that is then extruded to form the desired product.

User-Friendly Operation: With a simple press of a button, the Agitating Extruder can be set into motion. This ease of operation minimizes the need for extensive training and reduces the potential for operator error.

Energy Efficiency and Environmental Friendliness: Designed with energy conservation in mind, these extruders boast high operational efficiency with low energy consumption. Their minimal environmental impact aligns with the growing emphasis on sustainable practices in the construction industry.

Customizable Drying Systems

Understanding that different materials and project requirements call for different approaches, Yixing Keli offers various types of drying systems. These systems are designed based on the characteristics of raw materials tested in the laboratory and according to product specifications and capacity requirements. This customization ensures that the Agitating Extruder can be adapted to meet the specific needs of any operation, enhancing its versatility and applicability.

Applications in the Construction Industry

The versatility of Agitating Extruders makes them indispensable in the construction industry. They are used for:

Mixing and Extruding Concrete: The machine can handle the mixing of various components of concrete, ensuring a uniform mix that can be extruded into different forms and shapes as required.

Processing Mortar: Mortar, a critical component in masonry work, can be efficiently mixed and extruded using the Agitating Extruder, ensuring consistency and quality in the final product.

Forming Gypsum Products: Gypsum, used in the production of plaster and drywall, can be processed with precision, thanks to the machine's ability to mix and extrude with accuracy.

Why Choose Yixing Keli's Agitating Extruders?

When it comes to choosing the right mixing extruder, Yixing Keli Building Materials Machinery Equipment Co., Ltd. turned to us for several reasons:

1. Commitment to Quality: Yixing Keli is well-known for producing high-quality, reliable and efficient machinery. Their mixing extruders are no exception, with performance that meets or even exceeds industry standards.

2. Innovation: The company is at the forefront of innovation, constantly researching and developing new technologies to improve the efficiency and effectiveness of their machinery.

3. Customer Satisfaction: We value customer satisfaction and provide comprehensive after-sales service and technical support.

4. Customization: We offer customization options to tailor mixing extruders to customer-specific requirements.

The Working Principle of the Agitating Extruder

The working principle of an Agitating Extruder is based on a combination of mechanical agitation and extrusion. Here's a simplified breakdown of the process:

Material Input: Raw materials are fed into the extruder's hopper.

Mechanical Agitation: Inside the machine, a series of rotating screws or paddles agitate the materials, ensuring a thorough mix. This agitation process is crucial for achieving a uniform blend.

Extrusion: Once mixed, the materials are forced through a die or mold under pressure. This extrusion process shapes the material into the desired form.

Output: The extruded material is then cut or formed into the final product, ready for use in construction projects.

Conclusion

Agitating Extruders are a testament to the power of innovation in the construction industry. They offer a solution that combines efficiency, precision, and durability, making them an invaluable asset for any construction project. With Yixing Keli Building Materials Machinery Equipment Co., Ltd. at the helm, the future of construction material processing looks promising. As the industry continues to evolve, so too will the capabilities of Agitating Extruders, ensuring they remain at the forefront of construction technology.

Agitating Extruders vs. Traditional Extruders: A Comparative Analysis